Advertisements

Products and Services

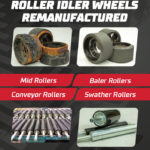

The Rubber Shop is an example of the craftsmanship that has grown with the company. Besides custom-designed steel and rubber moulded products, Fort Garry Fire Trucks relines hi-rail wheels for railways and makes rubber tarp straps. It also performs work for the mining and printing industries including installing rubber liners in tanks and remanufacturing press rollers.

ROLL PRODUCTS

Quality recovered rollers manufactured to precise and exacting specifications. Fort Garry is a supplier you can depend on, offering you quick turnaround and the confidence our products will always be of the highest standards available in the industry.

MATERIALS

All of our compounds are custom milled to equal the performance of O.E. rollers. The most common applications of some of the compounds we stock are shown below. Because of this wide variety, we are capable of recovering almost any type of roller in the Printing and Allied Industries.

ROLLER TYPE

MATERIALS

Sheet-fed, Letter press Rollers

PVC/Nitrile Base (15-50 Duro)

High speed Sheet-fed, Web Press Rollers

LHB/Nitrile Base (25-50 Duro)*

Flexograph Rollers

HG Neoprene (60-80 Duro)

U.V. Coaters, Elevated Temp. Applications 3000°F

EPDM (30-50 Duro)

Laminators, High Temp. Applications 5000°F

Silicone (40-80 Duro)

* The LHB/Nitrile is proving itself to be a superior compound. Its resistance to heat buildup presents a roller which is more dimensionally stable, and maintains its durometer reading longer, thus increasing the life of the roller.

INSPECTION

Journal inspection is performed prior to commencing any work, to detect damaged journals. If damage is found, repairs are executed to ensure quality rollers.

Detailed visual inspections of the surface, diameter measurements, and durometer readings are all taken to determine possible regrinds.

A T.I.R. (Total Indicated Runout) check is performed to ensure the trueness of the journals once any roller regrinds are complete. Maximum allowed .002″

Finished diameter is measured to ensure straightness. Maximum allowable taper is .002″.

We measure the face length to ensure correct transfer surface.

Magnified visual inspections of surface ensure a smooth and flaw free surface, and a final durometer reading is conducted to ensure proper hardness.

Standard Delivery

Crisis Delivery

Lined Products

Surface Preparation

Adhesive and Linear Applications

Vulcanization

Inspection

Repairs